RMG Crane

RMG crane is a rail-mounted container gantry crane, mainly used for transfer between container yards and chassis trucks. It is fixed on the track in the cargo yard and can only move along the track. It is equipped with a 20′ or 40′ retractable spreader (it can also be equipped with a double-container spreader as needed). It can be lifted and lifted within the specified range of the container yard. Stacking containers.

RMG cranes have the following features:

- Orbital design: The RMG crane adopts an orbital design, which is similar to the RTG crane, but can only move along the track. This design gives the RMG crane high stability and low energy consumption.

- Fixed on rails: RMG cranes are fixed on rails in the cargo yard and cannot move freely like RTG cranes. This makes the RMG crane suitable for transferring containers between the yard and the chassis.

- Efficiency: RMG cranes can quickly lift and stack containers within the specified range of the container yard, improving loading and unloading efficiency.

- High stability: Because the RMG crane adopts a track-type design, it has high stability and can withstand larger loads and adapt to different terrain environments.

- Low energy consumption: RMG cranes use advanced electric drive devices, which have high energy efficiency and low operating costs.

- High safety: RMG cranes are equipped with a variety of safety devices, such as limit switches, buffers, anti-collision devices, etc., which can effectively ensure the safety of operations.

- Wide scope of application: RMG cranes can be applied to containers of different specifications and types, and can also adapt to different loading and unloading requirements and site conditions.

- Easy maintenance: The structure and components of the RMG crane are relatively simple and easy to maintain, which can extend the service life of the equipment.

Reliable Rail-Mounted Gantry (RMG) Crane Supplier in Indonesia

The Dongqi Rail-Mounted Gantry (RMG) crane is the product of decades of crane design experience and knowledge. It incorporates a host of technological innovations, including the smarter cabin with video and monitoring technology that provides superb visibility to container handling operations. We can tailor your RMG for your specific operation.

Learn more about our RMGs

The rail type container gantry crane is a specialized gantry crane with a lifting capacity of 50 tons (40.5 tons under the lifting appliance), working levels of A6~A7, 40 tons (35 tons under the lifting appliance), and working levels of A5~A6. It is mainly used for container loading, unloading, handling, and stacking work in railway, port, dock container transfer yards, and large container storage and transportation yards. It is composed of the main beam, rigid and flexible door legs, running trolley, lifting mechanism, rotating mechanism (optional: lifting tool rotation, upper trolley rotation, hook type), crane running mechanism, electrical system, operating cab, etc. 20 ‘, 40, 45’, and 40.5t electric telescopic lifting appliances can be selected for container gantry cranes, with intelligent control and remote control; Multiple anti swing devices and methods ensure safety and accuracy during the lifting process, improving work efficiency; The design, manufacturing, and testing of the crane comply with the provisions of GBT 19683-2005 “Rail mounted Container Gantry Cranes”.

According to the yard operation process, extending the cantilever in the direction of a single or double door leg becomes a single or double cantilever model, and not extending becomes a non cantilever model. Different structural forms of non cantilever, single cantilever, and double cantilever are determined based on the site, container storage and transportation process, and loading and unloading vehicles (container trucks or railway vehicles).

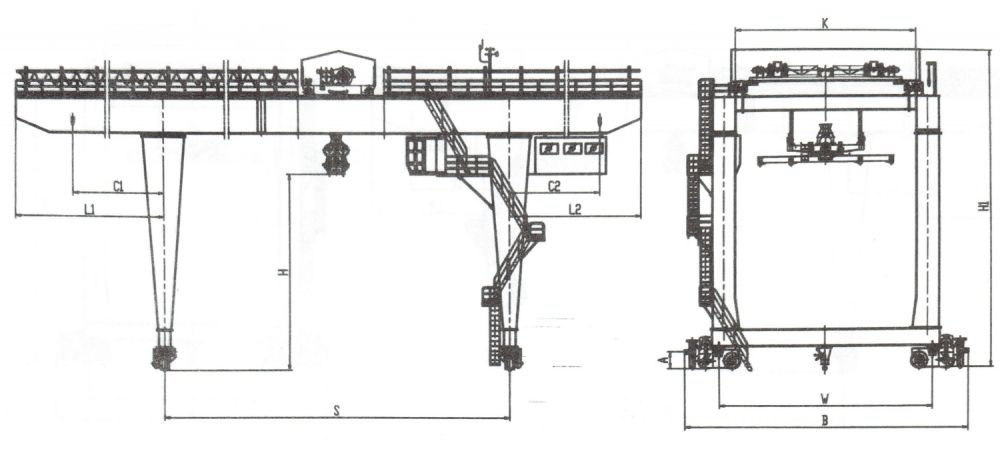

Outline Dimensional Drawing of 50 Ton Rail Container Gantry Crane

50-ton rail-mounted container gantry crane technical parameters and main dimensions data sheet

| Lifting capacity | t | 50 (40.5t under spreader) | |||

| Span(S) | mm | 26000 | 30000 | 35000 | |

| Lifting height(H) | 10000 | ||||

| work system | A6-A7 | ||||

| speed | Rise | m/min | Fully loaded 1.2-12 Unloaded 1.2-18 | ||

| Lower trolley operation | Fully loaded 4-40 Unloaded 4-60 | ||||

| Upper trolley operation | 1.5r/min | ||||

| Cart running | Fully loaded 4-40 Unloaded 4-60 | ||||

| electric motor | Rise | KW | 2x55KW | ||

| Car running | 2×7.5KW | ||||

| Cart operation | 4x11KW | 4x15KW | |||

| Maximum wheel pressure | KN | 348 | 370 | 395 | |

| Number of wheels | 8 | ||||

| Recommended rails | QU80-QU100 | ||||

| power supply | Three-phase AC 50HZ 380V | ||||

| Main dimensions (mm) | K | 8100 | |||

| W | 9600 | ||||

| B | 12600 | ||||

| A | 950 | ||||

| H | 10000 | ||||

| H1 | 17000 | ||||

| L1 | 8500 | 10500 | 12000 | ||

| C1 | 5500 | 7500 | 9000 | ||

| L2 | 8500 | 10500 | 12000 | ||

| C2 | 5500 | 7500 | 9000 | ||

Get Your Rail-Mounted Gantry Crane From Us!

We are the leading crane supplier in Indonesia, that offers gantry crane solutions ranging from 1 to 500 tons in accordance with ISO standards. If you are interested in finding out more about gantry cranes in Indonesia, please do not hesitate to contact us.

Looking for another type of crane? Check out our other products like overhead cranes, jib cranes and monorail cranes in Indonesia now.